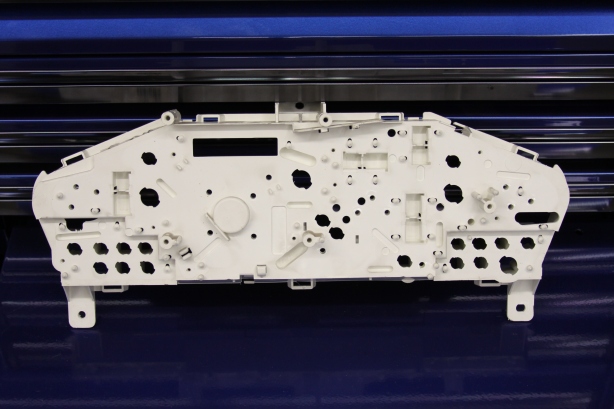

My absolute favorite thing about my day job is installing 12-volt electronics where they do not easily fit and making it look like they came that way from the automobile manufacturer. In this case, it was installing the new Alpine X009-U 9″ head unit into the dash of a 2003 Ford F-350. As you can see in the images below, the X009-U is virtually the same height as the Ford double DIN radio and climate controls combined… and quite a bit wider!

Since the X009-U will need to be custom installed into pretty much every vehicle out there, Alpine graciously supplies a trim ring that can be molded into the dash. This makes it a tad bit easier on the installer and gives him/her a nice starting point. Said trim ring can be seen in the previous two images.

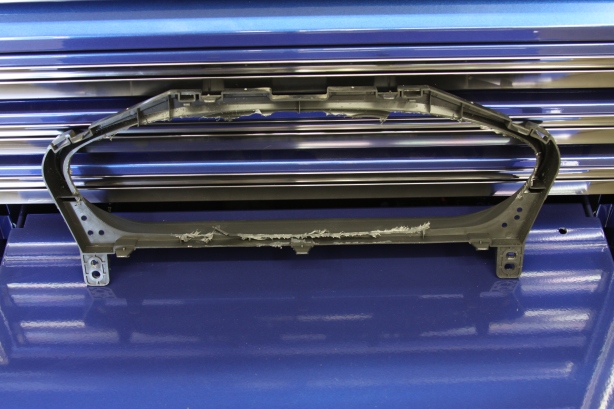

First thing is to cut a VERY large opening in the dash panel to house this behemoth of a head unit’s trim ring. I then like to hold the ring in place with superglue, in a few key places. This will hold the ring in place while I permanently glue it in place with Norton Speed Grip 2-part plastic epoxy:

Once the epoxy is set up, I then grind/sand any extra off that squeezed through to the front. I make sure to maintain the shape of the trim ring to the front of the OEM dash panel. In the next image, you will notice that I had to build up a section under the head unit buttons to make for a seamless transition from the Alpine trim ring to the OEM dash panel. For this I use Evercoat Fiber Tech, which is a Kevlar reinforced filler. I then use Evercoat Rage Gold for any “fine tuning”:

Once I was happy with shape of everything and filled any little pin holes etc., I sprayed the entire panel with several light coats of texture to get back to the OEM textured finish. For this texture I like to use SEM Satin Black Chip Guard:

Once the texture coat dried, I applied a OEM matching top coat to give its final finish:

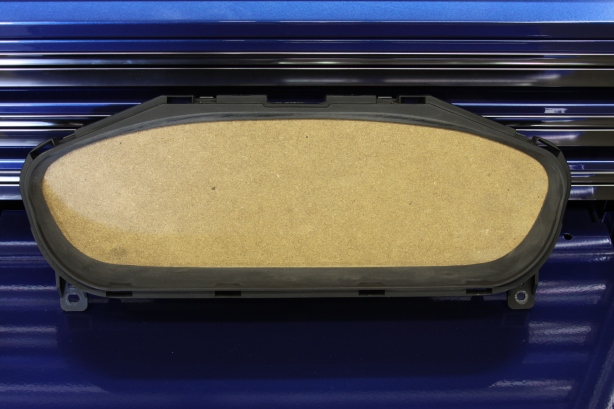

Now that the dash panel was basically finished until final install, it was time to find a good place for the climate controls. Luckily there is a pocket below the dash panel that is of little use. Although the pocket itself isn’t near large enough to house the climate control, the surrounding area is:

The first thing to do was hack the pocket out of there with an air saw:

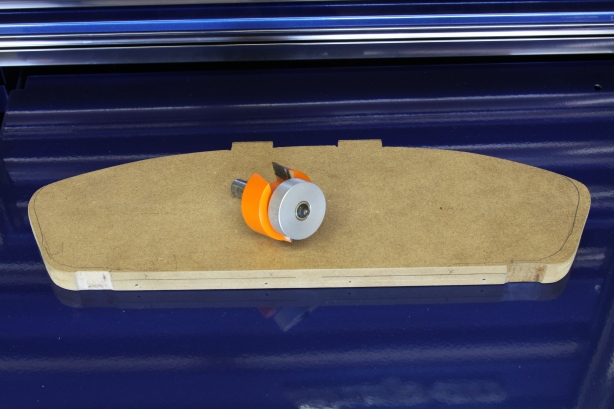

It was immediately clear that I was going to need to build this area out a little to make room for the climate controls to be rear mounted. So I made a perfect frame out of a solid piece of 1/4″ ABS. This would give me a framed-in area to rear mount the climate control and also give me a place to build onto to get the shape I want for that area of the panel. A quick test fit before trimming it a little on the corners and then tacking it in place with super glue:

Just like the head unit trim ring, I used the Norton Speed Grip to permanently bond it in place:

Again, I rough sanded the Norton Speed Grip and then used the Evercoat Fiber Tech to build up the transitions to the OEM panel. This is after rough sanding and using some more Evercoat Rage Gold filler for the finishing work:

A quick coat of texture in the modified area, some sanding to blend to the panel, just to check to make sure my shaping was good etc:

I then used the same 1/4″ ABS and Norton Speed Grip to make mounts for the climate controls to screw to the backside:

A quick test fit of the climate control:

A complete texture coating of the panel:

And finally the OEM matching color and mounting of the climate control:

Now that all the panels were finished, it was time for what I consider the hardest part… securely mounting the head unit in the dash. This is typically very time-consuming since there isn’t really any mounting points for the new radio. It needs to be EXACT so that when the dash panel is secured back onto the dash, the head unit sits perfectly into the opening I just created. The first thing is to cut out supports that are in the way etc. The new head unit is huge, so it needs space! Then it’s a matter of coming up with a mounting system that I can attach into the dash and is adjustable so I can fine tune the fitment as I go. So there is a lot of putting the dash panel on, take it back off, adjust the head unit a little, but the dash back on, take it back off, adjust again, put the dash panel back on…. you get the idea. I did not take any pictures of this as it’s behind the scenes and boring. So you will just need to take my word for it when I say this thing isn’t budging.

Installed images: